FESTO's automated solutions for electric vehicles

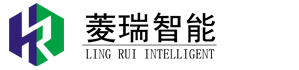

Electric Powertrain Production Line

The automotive industry is in a state of constant flux. Electric mobility is part of the future, and the number of electric cars and commercial vehicles will continue to grow. Established processes, structures, values, and supply chains are changing. New drive and vehicle technologies are placing ever-increasing demands on production technologies that are not only flexible but also intelligent and highly efficient. Quickly assembling flexible production lines, FESTO Utilizing extensive expertise in engineering and industry to ensure customer production performance is reliable and future-proof. FESTO Providing perfect solutions for complete powertrains, driving customer projects forward.

Press shop high precision gripping

The minimum requirement here is that the equipment must work accurately and flawlessly while applying enormous pressing force and operate at the highest possible speed. Functional safety is paramount. For press shops, we primarily offer solutions that ensure ultra-precise handling and gripping, which have proven to be reliable, durable, and economical. This includes conveyor separators and metal feeding, clamping, lifting and transporting.

For example FESTO the OVEM and OVEL vacuum generators are compact and combine vacuum generation and monitoring. OVEM They feature integrated throttling, with an integrated energy-saving module. Using a check valve, stopping does not waste unnecessary compressed air. Both vacuum generators are maintenance-free.

Another advantage is: Using integrated IO-Link technology, making the vacuum generators compliant with Industrial IoT requirements. 。

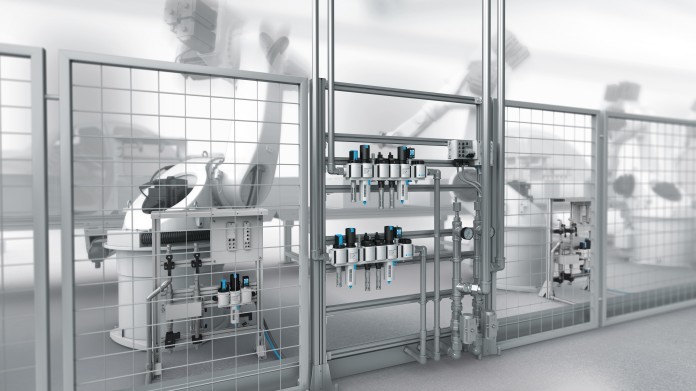

Precise welding and gripping in the body shop

Body manufacturing operations are carried out by welding robots. Here, reliable solutions are necessary to accurately and repeatedly position metal sheets, supply small parts to the production line, and supply compressed air and water to the welding guns. Festo focuses on using the Industrial Internet of Things in the body shop and has developed components specifically for pneumatic servo welding guns. We offer complete application-specific solutions for reliable supply of compressed air and cooling water for individual welding robots or complete welding lines. The design is pre-tested and tailored to body shop specifications, ensuring an orderly, centralized supply of media. This ensures reliable reproducibility of the weld points.